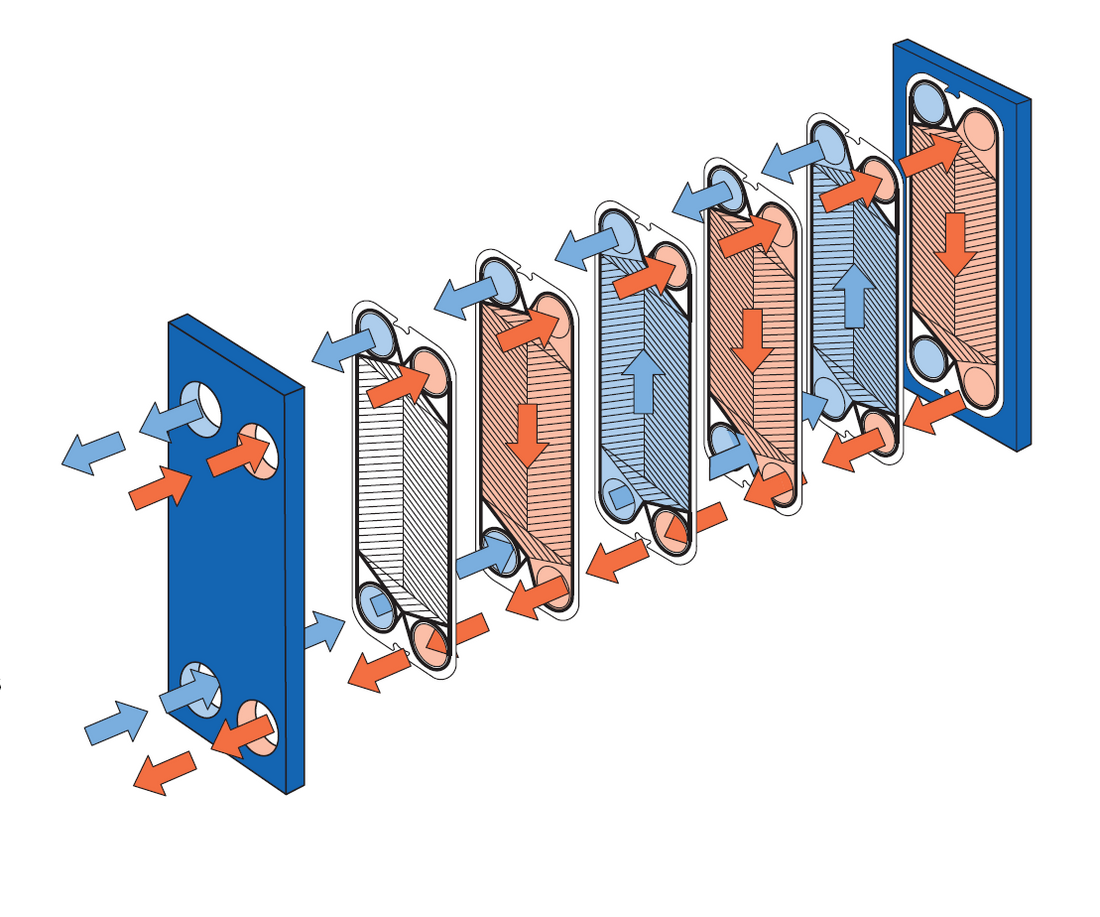

How it works - plate heat exchanger

The functionality of a copper brazed plate heat exchanger is based on the efficient transfer of heat between two fluids flowing along closely spaced copper plates. This happens in the following steps:

-

Inlet of fluids: The two fluids to be exchanged, typically a hot and a cold fluid, are introduced into the plate heat exchanger. They enter the narrow channels between the copper plates through separate inlet openings.

-

Countercurrent principle: The fluids flow in opposite directions along the channels between the plates. This countercurrent principle enables efficient heat transfer as it maximizes the temperature difference between the fluids.

-

Heat Transfer: As the fluids flow along the channels, heat transfer occurs. The heat is transferred from one fluid to the copper plates and from there to the other fluid. This occurs through direct contact and heat conduction via the copper plates, which are excellent heat conductors.

-

Turbulence: The wave-like structure of the plates promotes turbulence in the fluid flow. This helps ensure even distribution of fluids across the entire surface of the panels and increases heat transfer efficiency.

-

Compact design: Due to the compact design of the copper brazed plate heat exchanger and the high thermal conductivity of copper, the heat transfer efficiency is particularly high, and the space required for the device is small.

In summary, the functionality of a copper brazed plate heat exchanger enables efficient heat transfer between two fluids, with copper plates and the countercurrent principle ensuring high efficiency. This makes copper brazed plate heat exchangers the optimal choice for temperature control and heat transfer in many applications.