Your partner for plate heat exchangers and heating circuit distributors

Reliable solutions for efficient heat – Find the right products for your needs

Discover a comprehensive selection of high-quality plate heat exchangers and heating circuit manifolds. Our solutions are versatile and optimized to ensure efficient heat transfer in a wide range of applications.

Your favorites

-

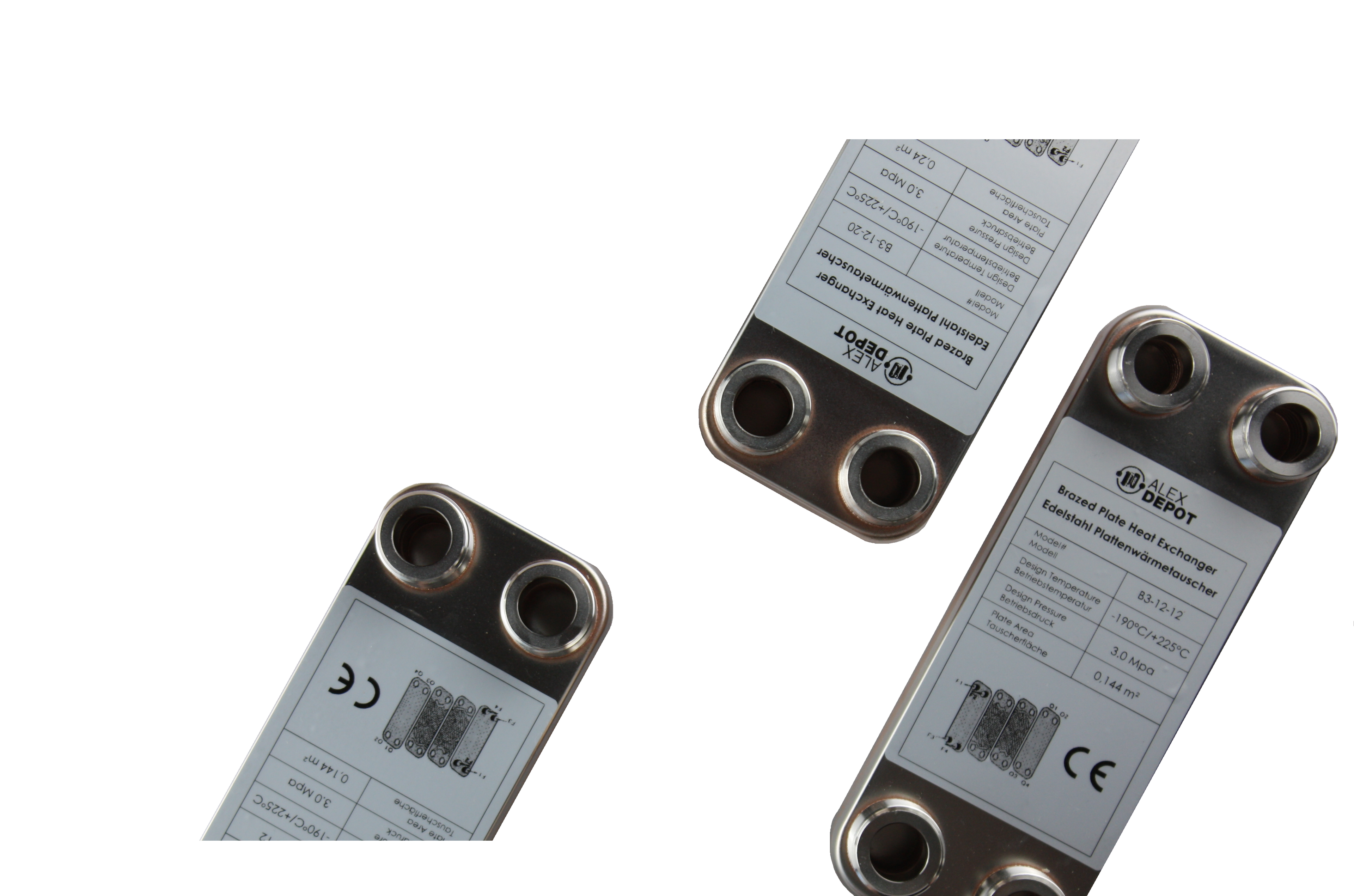

Plate heat exchanger B3-32-50 - 285kW, 50 plates

Vendor:alex-depotRegular price From €269,00 EURRegular priceUnit price / per -

Plate heat exchanger 12-30 - 65 kW, 30 plates

Vendor:alex-depot5.0 / 5.0

(1) 1 total reviews

Regular price From €69,00 EURRegular priceUnit price / per -

Plate heat exchanger B3-12-12 - 25kW , 12 plates

Vendor:alex-depot5.0 / 5.0

(1) 1 total reviews

Regular price From €44,00 EURRegular priceUnit price / per€0,00 EURSale price From €44,00 EUR -

Plate heat exchanger B3-12-30 - 65kW, 30 plates

Vendor:alex-depotRegular price From €59,00 EURRegular priceUnit price / per -

Plate heat exchanger B3-12-60 - 130kW, 60 plates

Vendor:alex-depotRegular price From €109,00 EURRegular priceUnit price / per -

Plate heat exchanger B3-32-20 - 115kW, 20 plates

Vendor:alex-depotRegular price From €159,00 EURRegular priceUnit price / per

PLATE HEAT EXCHANGER

Our plate heat exchangers offer you maximum efficiency and optimal heat transfer for your heating system. Discover our powerful models that are perfectly tailored to your individual requirements.

-

Shipment tracking

After your order has been dispatched, we will keep you informed about the delivery status. Shipping within Germany is free!

-

Carefree return

You have 30 days to complete your return easily and stress-free – without any hassle!

-

3 year guarantee

If you encounter any problems with your product, please do not hesitate to contact us using the contact form!

-

Professional advice

We will be happy to advise you when purchasing so that you can find the right product for your needs.

More efficiency with precisely fitting insulation shells

Insulation shells make a significant contribution to increasing efficiency by improving heat transfer. By reducing heat loss, maximum energy utilization is ensured, which not only optimizes heating performance but also leads to noticeable cost savings.

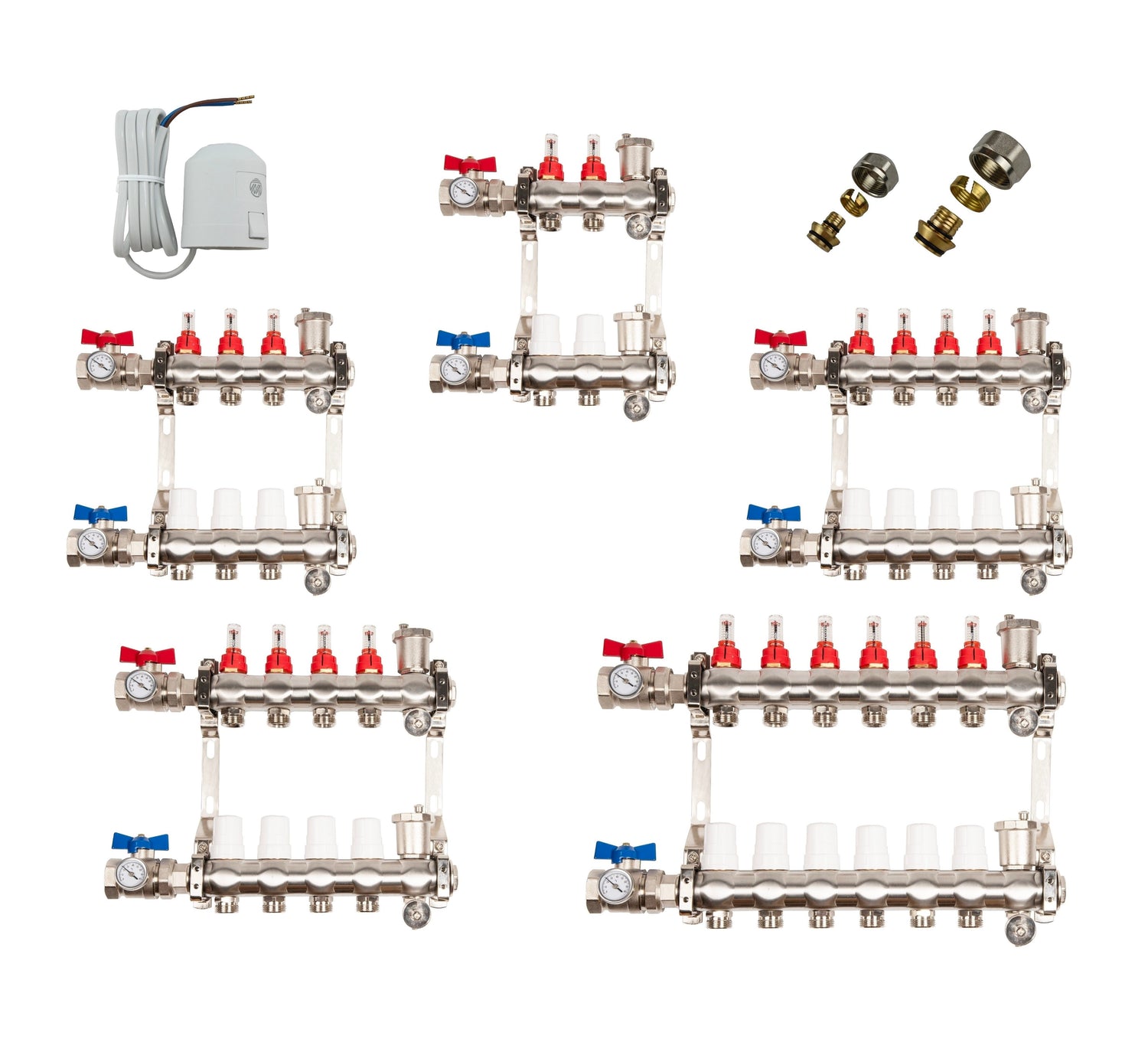

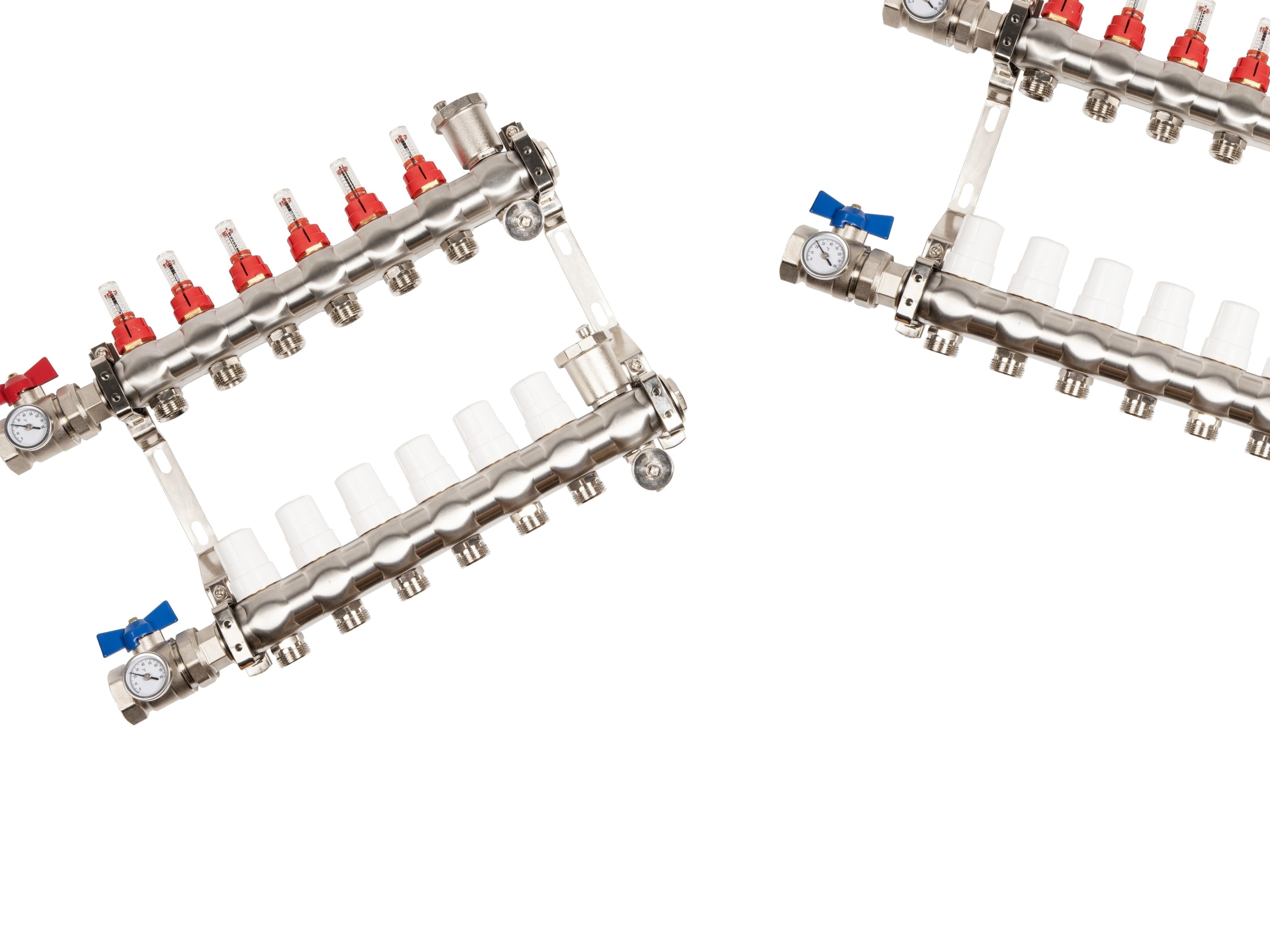

HEATING CIRCUIT DISTRIBUTOR

Our high-quality heating circuit distributors ensure precise control and even heat distribution in every room. Discover robust solutions that are optimally tailored to your heating system and ensure efficiency and comfort.

B2B - Business Inquiries

Contact us for customized B2B solutions, including volume discounts and regular deliveries. We are ready to meet your business needs.

Our latest posts

-

Advantages of copper soldering

Learn why copper increases the energy efficiency of plate heat exchangers and how it contributes to cost savings and a longer service life.

Advantages of copper soldering

Learn why copper increases the energy efficiency of plate heat exchangers and how it contributes to cost savings and a longer service life.

-

How it works - plate heat exchanger

The secret of efficient heat transfer lies in the use of the countercurrent principle. Find out why copper brazed plate heat exchangers are so effective!

How it works - plate heat exchanger

The secret of efficient heat transfer lies in the use of the countercurrent principle. Find out why copper brazed plate heat exchangers are so effective!

-

Benefits of Insulation

PUR rigid foam insulation optimizes the efficiency of your plate heat exchanger and minimizes energy loss. Find out more about the advantages in the article.

Benefits of Insulation

PUR rigid foam insulation optimizes the efficiency of your plate heat exchanger and minimizes energy loss. Find out more about the advantages in the article.

-

Structure - Plate heat exchanger

Discover how copper-brazed plate heat exchangers enable efficient heat transfer thanks to their special design and are convincing in many applications.

Structure - Plate heat exchanger

Discover how copper-brazed plate heat exchangers enable efficient heat transfer thanks to their special design and are convincing in many applications.

Let customers speak for us

from 4 reviewsFrequently asked questions

How do I receive an invoice for my order?

If you require an invoice with VAT shown, please send us a request via our contact form or by email to info@alex-depot.de. We will then provide you with the invoice immediately.

How do I claim my warranty and return?

We offer a 3-year warranty on our products, which covers defects in materials and workmanship. In the event of defects within the warranty period, please contact us to discuss the process for a return or exchange. You have 30 days from receipt of your order to make returns. Please contact us to obtain a return authorization and clarify further steps. Make sure the products are in their original packaging.

When will unavailable products be available again?

If a product is currently unavailable, we will do our best to get it back in stock as quickly as possible. Please let us know if you are missing a specific product and we will see if we can get it for you ahead of schedule.

Is it possible to receive my order via express shipping?

Yes, we offer express shipping for an additional charge of €16.99. To use this option, please indicate that you require express shipping in the "Special Order Instructions" field in your shopping cart. We will then arrange for your order to be shipped as quickly as possible.

Do you offer customized plate heat exchangers?

Yes, we offer customized plate heat exchangers designed to meet our customers' specific requirements. If you require customized solutions, please contact us with your requirements and we will be happy to help you find the right heat exchanger for your application.

How do you calculate the average temperature difference?

The mean temperature difference of a plate heat exchanger can be calculated by several methods, depending on the type of heat exchanger and the specific conditions. A common method is the Logarithmic Mean Temperature Difference. Here is how you can calculate it:

Formula for the logarithmic mean temperature difference

LMTD = (ΔT1 - ΔT2) / ln(ΔT1 / ΔT2)

variables

- LMTD: logarithmic mean temperature difference

- ΔT1: Temperature difference at one end of the heat exchanger

- ΔT2: Temperature difference at the other end of the heat exchanger

Example

- Temperature of the hot liquid at the inlet (Th): 150 °C

- Temperature of the cold liquid at the inlet (Tc): 30 °C

- Temperature of the hot liquid at the outlet (Th'): 80 °C

- Temperature of the cold liquid at the outlet (Tc'): 60 °C

1. Calculation of ΔT1 & ΔT2

ΔT1 = Th - Tc = 150 °C - 30 °C = 120 °C

ΔT2 = Th' - Tc' = 80 °C - 60 °C = 20 °C

2. Calculation of the mean temperature difference

LMTD = (120°C - 20°C) / ln(120°C / 20°C)

LMTD ≈ 55.8 °C

How is the heat flow calculated?

Q = U * A * LMTD

- Q: heat flow (W)

- U: total heat transfer coefficient (W/m²·K)

- A: Heat transfer area (m²)

- LMTD: logarithmic mean temperature difference (K)

or

Q = ṁ * cp * LMTD

- Q: heat flow (W)

- ṁ: mass flow rate (kg/s)

- cp: specific heat capacity (J/kg·K)

- LMTD: logarithmic mean temperature difference (K)

How should I connect my heat exchanger?

cocurrent and countercurrent principle

The transferable heat energy of a plate heat exchanger is not only determined by the size of the exchange surface and the heat transfer coefficient (k), but is also significantly influenced by the flow directions of the media involved. If both media flow in the plate heat exchanger in the same direction, this is referred to as the cocurrent principle. If they flow but in opposite directions, this is the countercurrent principle.

The flow direction has a significant influence on the average temperature difference between the media, which in turn determines the efficiency of heat transfer.

Temperature curve with the direct current principle | Temperature curve with the countercurrent principle

Theoretical consideration of the connection options of a plate heat exchanger:

In this example we assume two media with the same heat capacity and the same mass flow.

- Medium 1: 80 °C

- Medium 2: 20 °C

With the cocurrent principle, the maximum temperature that can be reached for both media would be 50 °C, which corresponds to the mixing temperature. With the countercurrent principle, however, medium 2 could reach a temperature of up to 80 °C, while medium 1 can be cooled to 20 °C.

This means that the countercurrent principle allows a larger amount of heat to be transferred using the same exchange surface area.

How do I find the right plate heat exchanger for my application?

Finding the right plate heat exchanger doesn't have to be complicated. If you have any questions or need support, don't hesitate to contact us. We'll be happy to help you choose the right model for your needs.