B3-12-12 B3-12-1244,00€

In stock

|

B3-12-20 B3-12-2059,00€

In stock

|

B3-12-30 B3-12-3069,00€

In stock

|

B3-12-40 B3-12-4089,00€

In stock

|

B3-12-50 B3-12-5099,00€

In stock

|

B3-12-60 B3-12-60109,00€

In stock

|

B3-23-20 B3-23-2099,00€

In stock

|

B3-23-30 B3-23-30129,00€

In stock

|

B3-23-40 B3-23-40159,00€

Out of stock

|

B3-23-50 B3-23-50189,00€

In stock

|

B3-32-20 B3-32-20159,00€

Out of stock

|

B3-32-30 B3-32-30199,00€

Out of stock

|

B3-32-40 B3-32-40249,00€

In stock

|

B3-32-50 B3-32-50269,00€

In stock

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| layers Number of Plates | 12 | 20 | 30 | 40 | 50 | 60 | 20 | 30 | 40 | 50 | 20 | 30 | 40 | 50 |

| max. Power | 25 kW | 45 kW | 65 kW | 80 kW | 90 kW | 130 kW | 90 kW | 135 kW | 180 kW | 225 kW | 115 kW | 175 kW | 230 kW | 285 kW |

| view_in_ar Volume | 0,22 L | 0,36 L | 0,54 L | 0,72 L | 0,90 L | 1,08 L | 0,80 L | 1,20 L | 1,60 L | 2,00 L | 1,00 L | 1,50 L | 2,00 L | 2,50 L |

| Heat Exchange Area | 0,114 m² | 0,24 m² | 0,36 m² | 0,48 m² | 0,60 m² | 0,80 m² | 0,46 m² | 0,69 m² | 0,92 m² | 1,15 m² | 0,64 m² | 0,96 m² | 1,28 m² | 1,60 m² |

| Flow rate | max. 4 m³/h | max. 4 m³/h | max. 4 m³/h | max. 4 m³/h | max. 4 m³/h | max. 4 m³/h | max. 4 m³/h | max. 4 m³/h | max. 4 m³/h | max. 4 m³/h | max. 12 m³/h | max. 12 m³/h | max. 12 m³/h | max. 12 m³/h |

| weight Weight | 0,80 kg | 1,11 kg | 1,50 kg | 1,85 kg | 2,23 kg | 2,61 kg | 2,57 kg | 3,41 kg | 4,27 kg | 5,10 kg | 3,86 kg | 4,97 kg | 6,20 kg | 7,50 kg |

|

straighten

Size

(Length x Width x Height) |

L:191mm W:073mm H:034mm | L:191mm W:073mm H:052mm | L:191mm W:073mm H:067mm | L:191mm W:073mm H:097mm | L:191mm W:073mm H:112mm | L:191mm W:073mm H:127mm | L:315mm W:073mm H:052mm | L:315mm W:073mm H:074mm | L:315mm W:073mm H:096mm | L:315mm W:073mm H:119mm | L:286mm W:116mm H:058mm | L:286mm W:116mm H:082mm | L:286mm W:116mm H:103mm | L:286mm W:116mm H:135mm |

|

conversion_path

Connection

|

2x ½ & 2x ¾ or 4x ¾ inches |

2x ½ & 2x ¾ or 4x ¾ inches |

2x ½ & 2x ¾ or 4x ¾ inches |

2x ½ & 2x ¾ or 4x ¾ inches |

2x ½ & 2x ¾ or 4x ¾ inches |

2x ½ & 2x ¾ or 4x ¾ inches |

4x 3/4 inches | 4x 3/4 inches | 4x 3/4 inches | 4x 3/4 inches | 4x 1 inch | 4x 1 inch | 4x 1 inch | 4x 1 inch |

|

split_scene_left

Collection

|

B3-12 Collection | B3-12 Collection | B3-12 Collection | B3-12 Collection | B3-12 Collection | B3-12 Collection | B3-23 Collection | B3-23 Collection | B3-23 Collection | B3-23 Collection | B3-32 Collection | B3-32 Collection | B3-32 Collection | B3-32 Collection |

Product Information

Optimized efficiency with PUR rigid foam insulation shells

An uninsulated plate heat exchanger continuously releases heat to its surroundings. Our precisely fitting insulation shells made of durable PUR-rigid foam effectively counteract this and provide improved thermal insulation. With a material thickness of 20 mm and a thermal transmittance coefficient of approx. 1.1 W/(m²K), they significantly reduce heat loss. Compared to uninsulated systems, this enables an efficiency increase of over 90%! The insulation shells can be installed quickly and easily thanks to the simple plug-in assembly, and retrofitting is possible at any time. In addition, the closed surface offers protection against moisture, corrosion, or mechanical impact.

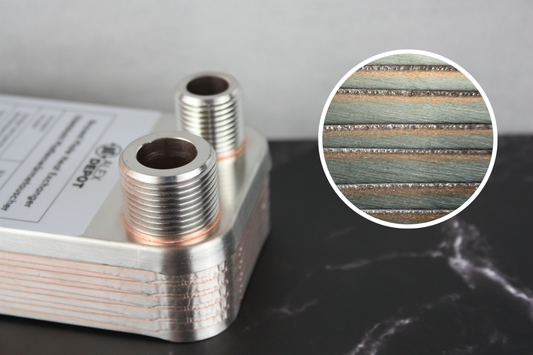

Your benefits with high-quality 99.9% copper soldering

Copper-brazed plate heat exchangers enable efficient heat transfer while maintaining high structural strength. The copper brazing creates a permanently stable bond between the stainless steel plates, which not only enhances thermal efficiency but also contributes to the durability of the heat exchanger. Thanks to the high thermal conductivity of copper, these plate heat exchangers are ideal for demanding applications that require reliable and powerful performance. Combined with plates made of 304 stainless steel, copper-brazed heat exchangers offer good corrosion resistance for a wide range of uses. This makes them a cost-effective solution for various heating, cooling, and industrial applications.

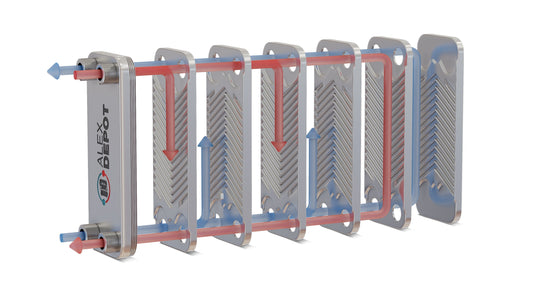

Design & Function of a Plate Heat Exchanger

Brazed plate heat exchangers consist of multiple stainless steel plates featuring an embossed pattern with oppositely aligned chevron grooves. All plates share the same shape but are alternately rotated by 180 degrees when stacked. This arrangement creates defined flow channels for both media while simultaneously forming contact points between the plates. Using a high-vacuum brazing process, the plates are joined at the contact points with copper brazing material, resulting in a robust and leak-proof connection.

The schematic illustration above shows the flow of the two media inside the plate heat exchanger. The hot medium enters from the right side and flows through every second channel until it reaches the opposite port. In parallel, the cold medium enters through the left port, flows through the alternating channels, and exits on the opposite left side. Although the two media are physically separated by the stainless steel plates, they are in direct thermal contact, enabling highly efficient heat transfer from the warmer to the cooler medium.

For optimal performance, we strongly recommend connecting the plate heat exchanger in a "counterflow" configuration. In this setup, the two media flow in opposite directions past each other, maintaining the highest possible temperature difference across the entire heat transfer surface. In contrast to the "parallel flow" configuration, where both media flow in the same direction, counterflow enables significantly more efficient heat transfer and thus more effective energy exchange. The following graphs illustrate the theoretically achievable outlet temperatures for counterflow and parallel flow configurations.

Parallel flow

Counterflow

In practice, heat losses, insufficient insulation, fluctuating flow rates, etc. may affect the results. Accessories such as insulation shells can help remedy this and improve efficiency. A detailed practical test can be found in our blog post.

Unique flow design for maximum efficiency

Due to the special embossing of the plates, a targeted turbulent flow of the media is generated, which significantly increases the performance of the heat exchanger and improves heat transfer. The resulting vortices enhance heat transfer by reducing heat build-up in the boundary layer on the plate surfaces. Normally, this layer acts as a barrier to heat exchange, but breaking it up significantly improves thermal conduction. Even when temperature differences are small or installation space is limited, the efficiency remains high. At the same time, the turbulence caused by continuous movement and strong wall shear stress ensures that particles do not adhere and deposits such as limescale cannot form.

Our Quality Promise

Since 2013, we have stood for reliable technology and the highest quality standards in the field of plate heat exchangers and underfloor heating distributors. Our products are carefully inspected and impress with durability, efficiency, and precise workmanship. That’s why we offer you a 3-year warranty that underscores our quality promise. In addition, you have 30 days to experience the quality for yourself and return the product if it doesn’t meet your expectations. This way, you buy without risk and with the confidence that you’ve made the right choice.

Plate heat exchangers are used in numerous applications where heat needs to be efficiently transferred from one medium to another. Here is an overview of typical application areas, although many other uses are possible.

- Underfloor heating

For hydraulic separation between the primary circuit (e.g., district heating or boiler) and the underfloor heating circuit – often with different system pressures, materials, or control requirements. - Solar systems / solar thermal

Transfers the heat generated in solar collectors to the heating or domestic hot water system – often combined with buffer tanks. - Domestic hot water preparation

For heating drinking water using heating water, either in a flow-through system or via storage tanks with integrated heat exchangers. - Refrigeration technology

Used as evaporators or condensers in refrigeration machines, air conditioning systems, and industrial cooling plants for heat absorption or release. - Heat pumps

Serve as evaporators or condensers to transfer environmental heat (from air, ground, or water) to the heating system. - Heating systems

For separating different heating circuits, for example with varying pressure levels, heat generators, or system requirements. - District heating

Transfers heat from the district heating network to the internal heating or domestic hot water system of the building (often in transfer stations). - Air conditioning systems

Enable heat exchange between cooling units (e.g., chillers) and room air or recirculation systems. - Building climate control

Support thermal distribution in central HVAC systems (heating, ventilation, air conditioning) of large buildings such as offices, hotels, or hospitals. - Swimming pool water heating

Transfers heat from the heating system to the pool water with complete separation of both circuits for material compatibility and operational safety. - Industrial heating technology

In processes where heat must be transferred precisely (e.g., in chemical, pharmaceutical, or food industries). - Heat maintenance

For utilizing available waste heat and maintaining a constant temperature level, e.g., in ventilation systems or production processes. - Heat supply networks

Enable decentralized distribution of centrally generated heat to multiple buildings or consumption units, often with individual transfer stations. - Combined heat and power plants (CHP)

Transfer waste heat generated during electricity production to heating or hot water systems, increasing overall energy efficiency. - Cooling circuits

Remove process heat or machine waste heat via water or glycol circuits, often in production plants or data centers.

Our latest posts

- Choosing a selection results in a full page refresh.

- Opens in a new window.