3 heating circuits 3 heating circuits94,00€

In stock

|

4 heating circuits 4 heating circuits114,00€

In stock

|

5 heating circuits 5 heating circuits129,00€

In stock

|

6 heating circuits 6 heating circuits134,00€

Out of stock

|

7 heating circuits 7 heating circuits149,00€

In stock

|

|

|---|---|---|---|---|---|

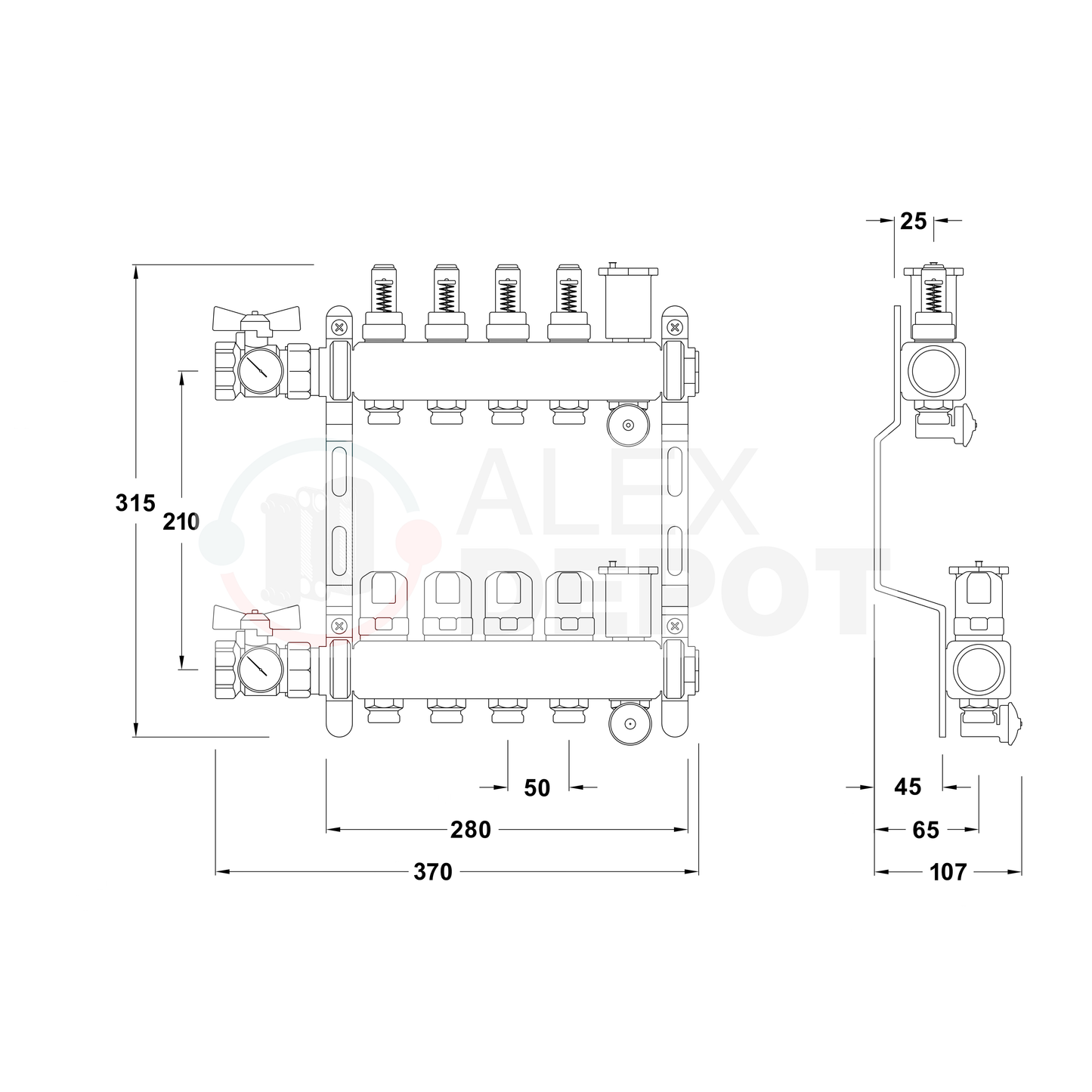

| layers Heating circuits | 3 | 4 | 5 | 6 | 7 |

|

straighten

max. Size

(Length x Width x Height) |

L: 320 mm W: 107 mm H: 315 mm |

L: 370 mm W: 107 mm H: 315 mm |

L: 420 mm W: 107 mm H: 315 mm |

L: 470 mm W: 107 mm H: 315 mm |

L: 520 mm W: 107 mm H: 315 mm |

Product Information

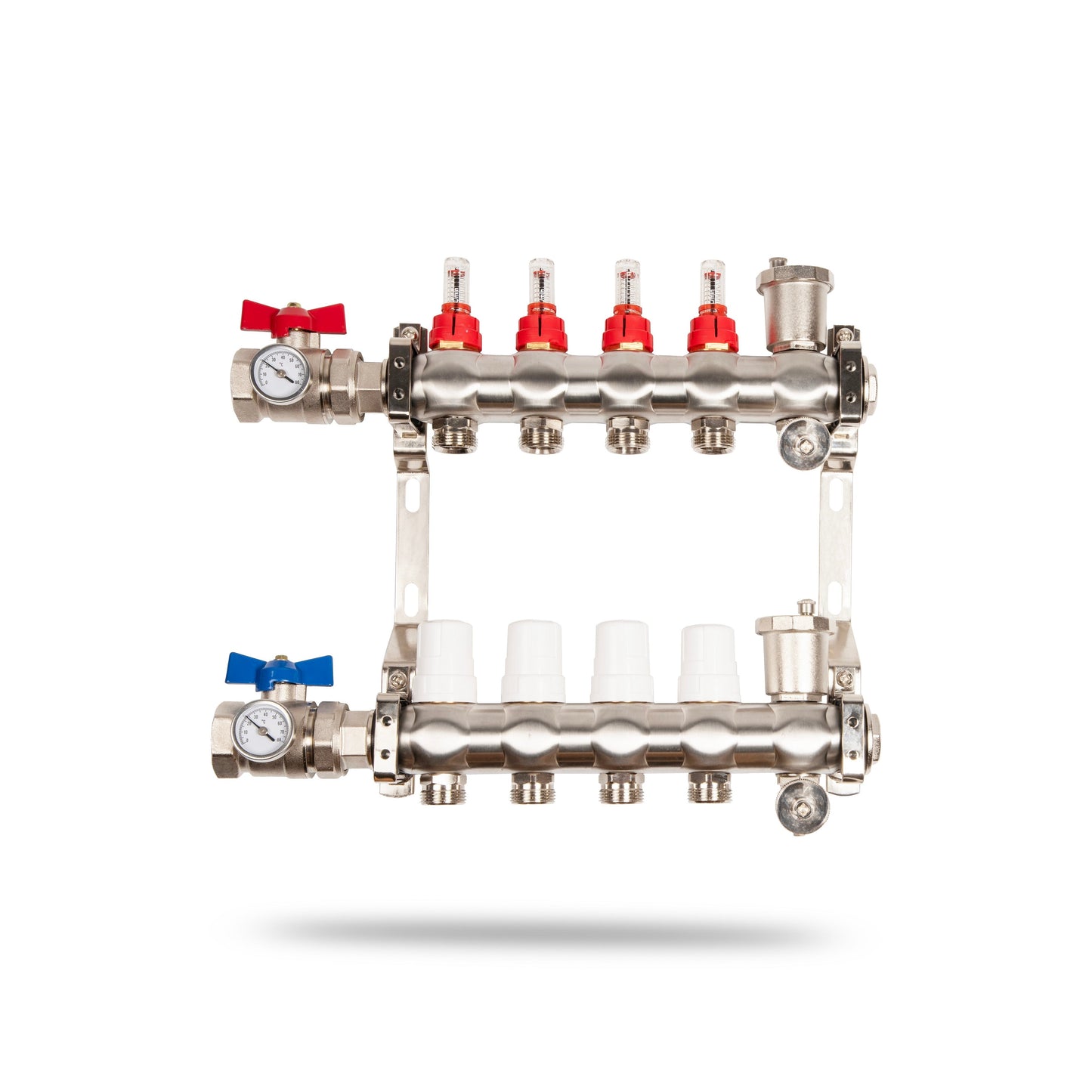

Central component of your surface heating system

The manifold is a central component of modern surface heating systems. By ensuring the even and demand-oriented distribution of heating energy to the individual heating circuits, it forms the heart of many floor, wall, or ceiling heating systems. Thanks to its precise control and regulation technology, the manifold enables an exact adjustment of heating output to the specific room requirements. The combination with modern control components such as actuators and room thermostats allows for zoned control, making individual temperature profiles achievable. Our manifolds are made of high-quality, corrosion-resistant materials and are distinguished by their durability, high operational reliability, and easy installation. Combined with suitable accessories and well-thought-out planning, the manifold represents a powerful, low-maintenance, and future-proof solution for all types of surface heating systems.

Well-designed construction, integrated safety

Manifolds with integrated automatic air vents offer a reliable solution for the optimization of system performance and operational safety. The built-in quick air vents continuously remove air from the water circuit, entirely without manual intervention. This effectively prevents the formation of corrosion-promoting oxygen, cavitation in the circulation pump, air pockets in the heating circuits, and pump dry running. The result is even heat distribution throughout the system, which not only increases energy efficiency but also significantly reduces disturbing flow noises. Thanks to their compact and low-maintenance design, these manifolds are ideal for modern heating systems where durability, efficiency, and high comfort are key priorities. Automatic air venting thus makes a crucial contribution to the long-term functional reliability of the entire heating system and is therefore indispensable.